In order to obtain a sufficient ballast compactness (at least a density of 1.6 t/m3), the "Dynamic Track Stabilization Machine" is absolutely necessary today to complete the tamping works. Indeed, the present tampers work mainly on two, three or even four sleepers at the same time, and while all the tamping tools are linked on a same housing, their penetration depth in the ballast and the squeezing times are identical.

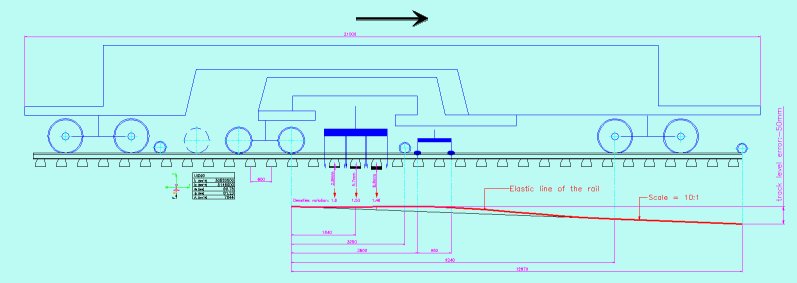

The above schematic shows clearly that when the lifting-lining clamp lifts the track for leveling, the deformation line of the rails is not a straight one.

Consequently the voids under the sleepers cannot be the same, as the three black rectangles under the sleepers on the above schematic demonstrate. On the contrary, these voids increase in the work direction (arrow).

All this indicates that to achieve a homogeneous and lasting ballast platform capable to support the track correctly, it is required to adjust on each sleeper the penetration depth in the ballast and the tools squeezing time. Since today it is not possible to do that, the involvement of the "Dynamic Track Stabilization Machine" is absolutely justified.

The above demonstration explains the reason why we developed a multiple head made up of identical modules, two per rail and per sleeper.

On every module the penetration depth in the ballast and the tools squeezing are adjusted by computer in function of the magnitude of the lift of the track.

Thus, the problem of the tamping quality obtained with the mentioned system, is solved. Consequently, there is no longer need for the "Dynamic Track Stabilization Machine".

Moreover, in our Tamping Machine project, we introduced for the first time a device measuring the realized ballast compactness during the tamping work, with which it is possible to adjust the compactness to desired values.

Last but not least, a modular system such as we have developed, is much simpler and cheaper to manufacture (series effect) than, i.e. a big three-heads-block and consequently its reliability is therefore much better.

| DRECO SA · Avenue des Mousquetaires 10 · CH-1814 LA TOUR DE PEILZ +41 21 973 1520 FAX +41 21 973 1522 · e-mail: info@dreco.ch  | 1 · 2 · 3 · 4 |